I. Raw Material:

Magnesite or hydromagnesite

II. Principle:

Conduct pretreatment of magnesite or hydromagnesite, resolve it through pulverizing and calcination and convert into magnesium oxide, and produce light-burned magnesium oxide powder through pulverizing and packaging.

III. Chemical Reaction:

MgCO3→MgO+CO2↑ - 121KJ

CaCO3→CaO+CO2↑ - 177.94KJ

IV. Consumption: (calculated according to 1,000kg finished products)

Magnesite 2-2.5T; coal 0.18-0.4T; and electricity 30-50Kw.h

V. Main Equipment:

Crushing equipment, vertical calcining kiln (or rotary calcining kiln), powder preparing equipment, packer, etc.

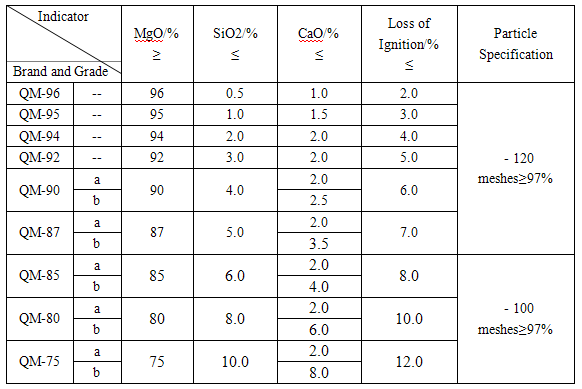

VI. Light-burned Magnesium Oxide Mass Indicator:

VII. Form of cooperation:

Technical transfer. Taking responsibility for process flow design, supporting equipment of standard equipment, non-standard equipment manufacture design, equipment is plane layout design, equipment installation design, pipe network design, equipment installation guidance, equipment commissioning, production commissioning, training for production engineers, analysis staff and technicians, process operation specifications, raw material and product analysis method, and preparation of intermediate control analysis method; ensuring output, yield and quality to reach the standard; and undertaking turn-key projects.